Description

Contact voltage isolation and waterproofing membrane

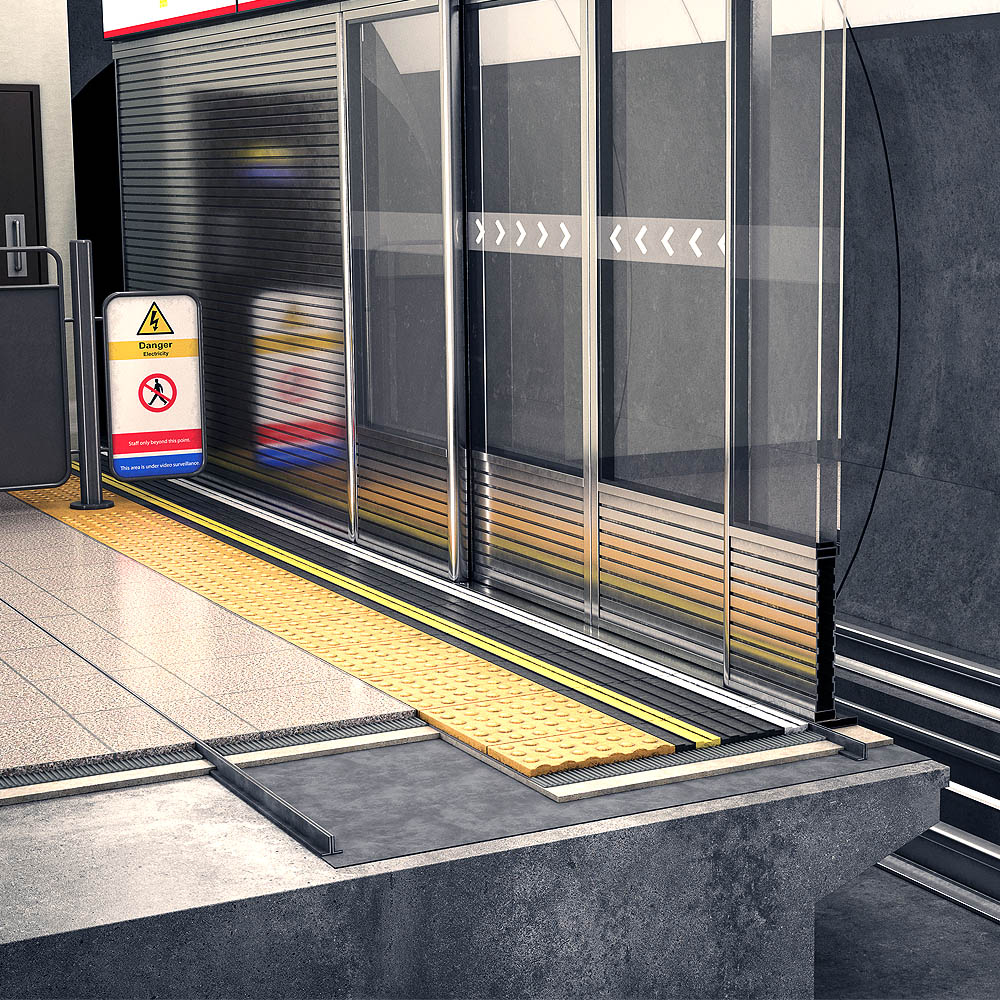

Isolatec CVIM is a Contact Voltage Isolation and Waterproof Membrane (CVIM) specifically formulated to prevent the transfer of static electrical current through concrete slabs and walls in both dry and wet conditions. Whilst suitable for a wide range of uses, Isolatec CIM helps protect passengers and workers boarding or working on electrified rail systems. It is a vital component in protecting passengers from static discharge where platform screen doors are installed.

With a thickness of 2.5mm the Isolatec CVIM has a volume resistivity of 5.73 x 10^14 ohm-cm and out performs all other known voltage isolation membranes of the same thickness.

Comprising a specially formulated butyl rubber membrane which contains neither bitumen nor bentonite, the Isolatec CVIM has a self-adhesive base layer for bonding the membrane to differing substrates such as concrete slabs and metalwork. This self-adhesive side of the membrane provides an instant high-strength bond to the surface of most major construction substrates.

The upper layer of Isolatec CVIM incorporates a non-woven polyester fleece surface layer. This layer allows the application of a variety of finishing materials including concrete and screed toppings as well as chemical and fire proof cement based materials. Through this fleece layer, the concrete and screed toppings will form a high-strength bond to the membrane and indirectly through the membrane’s self-adhesive layer to the underlying slab or other substrate.

Similarly a high-strength bond will be formed with plaster, render, cementitious coatings, resins, paints, tile adhesive and other similar materials applied in vertical and overhead planes.

This fully bonded system prevents delamination between the substrate and the topping which helps maintain the integrity of the floor, wall, column and ceiling finishes.

Isolatec CVIM also helps isolate finishes zones from movements in underlying substrates as it offers high crack-bridging characteristics up to 3mm. The flexibility of the butyl core absorbs these deflections and helps prevent substrate cracking from transferring through to fragile applied finishes.